The Ultimate Scopedog

If your mind works a certain way, the first thought that occurs to you when you lay eyes on Kunio Okawara’s brilliant Scopedog design is, “That could actually kinda work IRL.”

In fact, that was the whole point of it. After previous experiences designing anime mecha, Okawara set out to create something that would remain as intact as possible when it made the leap from a 2D drawing to 3D toys and model kits. Unlike most anime robots, it required no magic physics or structural compromises to accomplish that leap. As a result, the Scopedog has fascinated fans, engineers, modelers, and sculptors alike ever since.

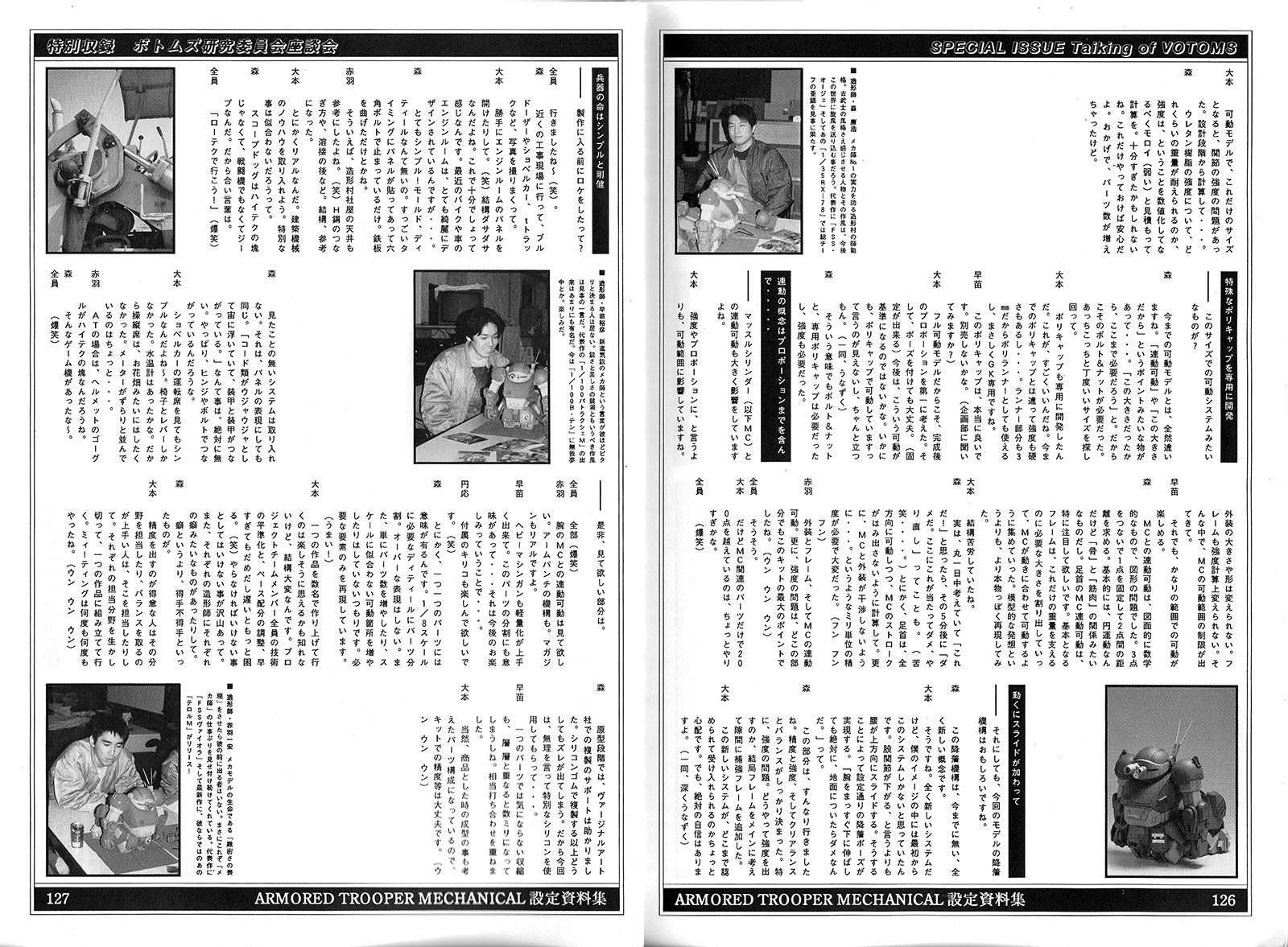

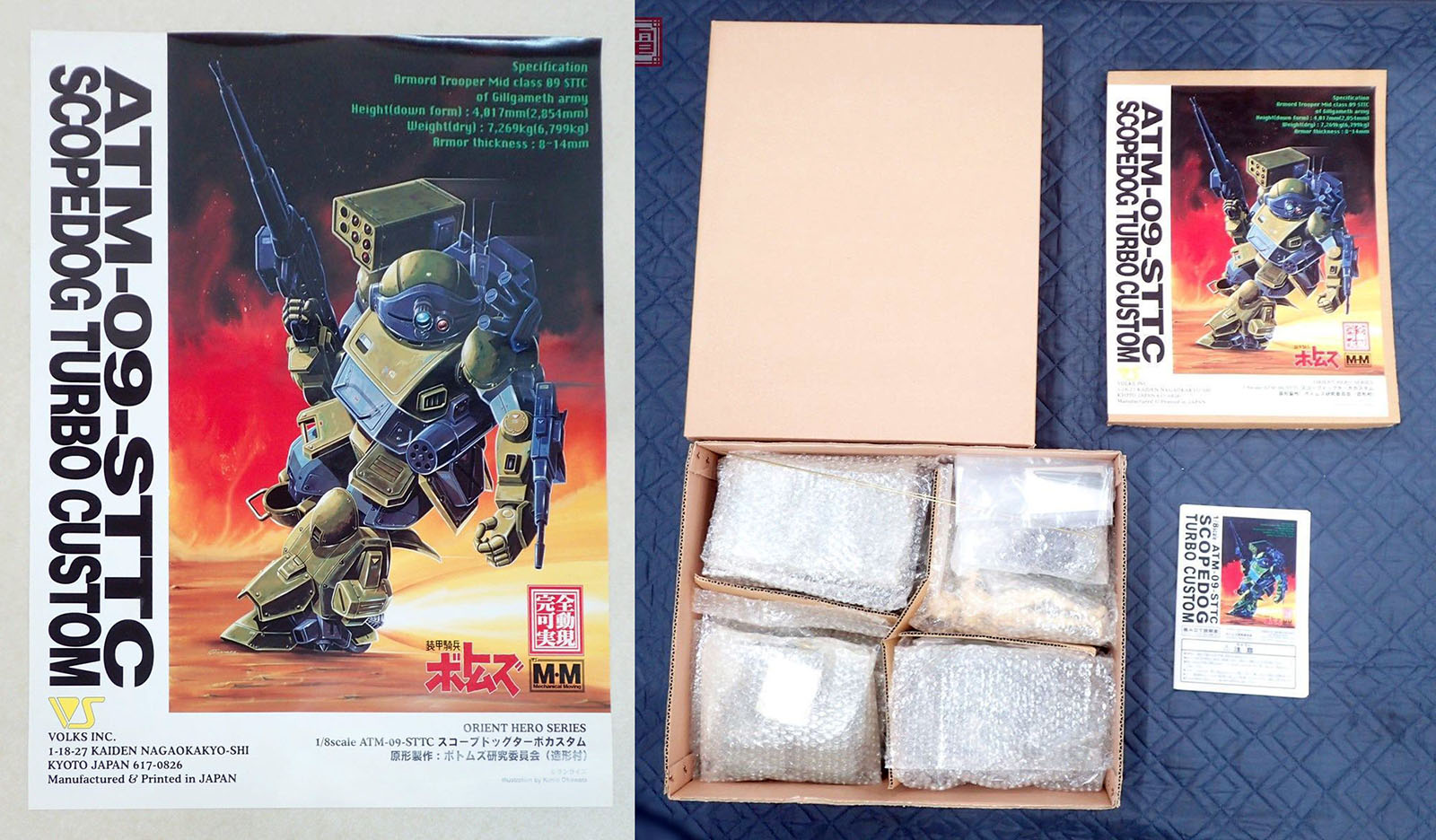

Hundreds of increasingly elaborate toys, plastic models and high-end garage kits have appeared since the Scopedog made its debut, all created by people who wanted to prove it could work IRL. In that way, it has become a timeless design and a constant challenge. In 1995, that challenge was taken up by a cutting-edge team of designers working for Volks, a highly-respected garage kit company in Japan. The result was the ultimate Scopedog; a 1/8 scale behemoth standing 20″ tall.

If size was all that mattered, it would have been topped when a Japanese metallurgist (named “Kogoro”) went all the way up to 1/1 scale ten years later. But the Volks team took an additional step by creating a “Mechanical Moving” model with working internal parts that required precision engineering skills never before applied to such a kit. The 1/8 Scopedog was released in December 1995, a Turbo Custom followed afterward, and both were upgraded for limited re-release in 2013.

Presented here is a 1995 round table discussion with the team, conducted shortly after they completed the model for reproduction. It was included in Armored Trooper Mechanical, a commemorative art book published by Volks that catalogued all the AT mecha designs that existed up to that time.

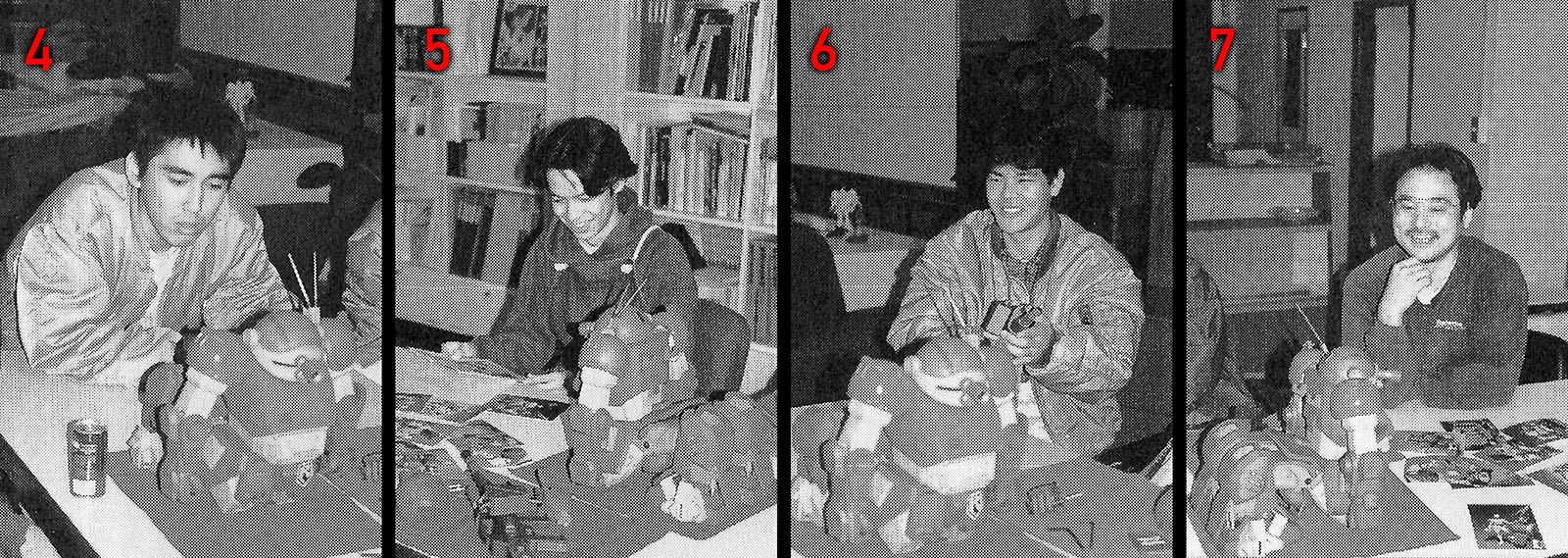

Votoms Research Committee Roundtable Discussion

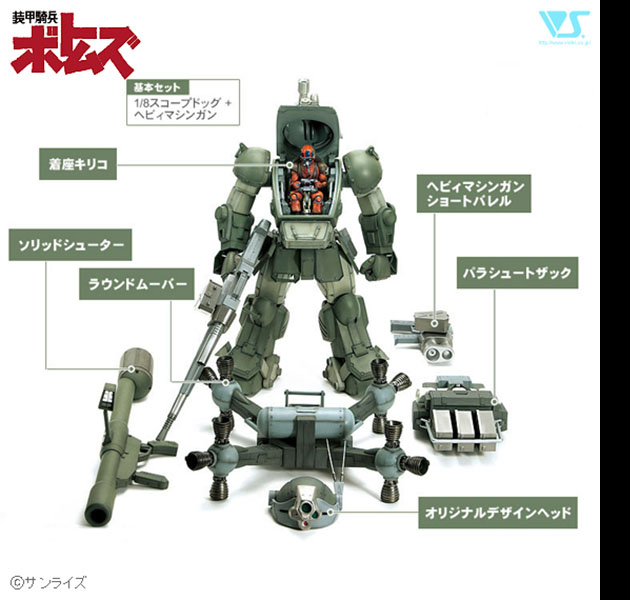

After all the hard work, the final round table discussion of the Votoms Research Committee was held. The faces of the “masters” who gave their all were glowing with relief and a sense of accomplishment. The average age of the participants was 26 years old. Zoukei-Mura (Sculpture Village) attracts the attention of fans around the world. Their hands will open up a great future. We thank you for your support.

To commemorate the publication of this book, members of the Votoms Research Committee gathered with members of Zoukei-Mura to discuss the history of Votoms models. We discussed the secret story of production of the 1/8 Scopedog prototype, which made a huge impact on the world of Votoms models. What topics will be discussed in the wake of this great achievement? We hope you will enjoy this honest conversation in the extradimensional world of the sculptor.

First of all, let’s briefly answer the question “What is Zoukei-mura Inc.?” Zoukei-mura was founded in 1992 in the suburbs of Kyoto, Japan, with the goal of “creating three-dimensional embodiments of heroes derived from the Orient.” In 1992, a workshop was completed in Kameoka City, a suburb of Kyoto. Currently, seven pro-sculptors kindle the flame of creation there in a quiet but passionate manner.

The workshop is located next to the site of “Virginal Art,” the production base for Volks garage kits, and has an area of 250 square meters, the largest in the industry. The comfortable environment and well-equipped facilities strongly support the creative activities of the sculptors.

Zoukei-Mura is a rare workshop. The numerous works produced there are sure to be greeted with high expectations and appreciation by fans around the world. This roundtable discussion was recorded in their meeting room.

The team members:

1. Kazunori Omoto, sculptor

He was the chief sculptor of the 1/8 Scopedog project, and his skill is intimidating. He has been working in this field for 7 years this year. His representative works include [from Patlabor] the 1/24 Ingram, 1/24 Griffon and many others. He is a talented sculptor of both mecha and figurines.

2. Yasuhiro Mori, modeler

He is the master of Zoukei-mura, the No. 1 mecha master. His figures and style, which have the style of ancient samurai, are sure to take the world by storm in years to come. His representative works include the [Five Star Stories] Auger and the 1/35 RX-78 Gundam, for which he served as chief of staff.

3. Hirohiko Sanae, sculptor

There is no one who can be described as an up-and-coming mecha artist as well as he can. His style of work, which can be described as a competition between sharpness and beauty, can be summed up in a single word: brilliant. His masterpiece, the “1/100 Patraoushe Mirage” [from Five Star Stories] is very famous. Now, he is absorbed in “1/100 B Ten.” We’re looking forward to seeing it.

4. Kazuhiro Akabane, sculptor

When it comes to the “expression of precision,” which is the life of mecha models, there is no one who can match him. He continues to show us the very essence of “mecha model” work. His representative works include ” Viola” [from Five Star Stories] and his latest work, “Terror M”, which only he could produce, has been released!

5. Fumihiko Enou, sculptor

Won a prize at the first Zoukei-mura Pro Contest! As a figure pro, it is no surprise that he has been making a name for himself lately. His neat masks and courteous manner are belied by his young age. It is no wonder that he already has a large number of “Enou fans.”

6. Noboru Ohashi, sculptor

Noboru Ohashi started his career at Yoyogi anime school. He has already become a member of the “1/8 AT” project! Despite his nervousness, he has fulfilled his great responsibility with gusto. He will be a member of the 1/24 Votoms team in the near future, so please give us your feedback.

7. Akihiro Enku, modeling master

Akihiro Enku is the guru of the garage kit world. He has been highly acclaimed by fans and sculptors not only in Japan but also in the U.S. and Europe. His “1/4 Hajime Sorayama WORLD” continues to draw endless applause. At home, he is a good father of two children.

First of all, a mockup is completed.

Interviewer: How did you proceed with the production of the prototype?

Omoto: We started with the mockup, making use of know-how from previous large-scale model production.

Mori: It was better for all the members of the project team to discuss the base model together. It would be easier to unify everyone’s individual images and to grasp the proportion and balance.

Sanae: As for the proportion, we were relieved to have Mr. Omoto, the “super Votoms guy,” on our side. (All laugh)

Interviewer: That’s why Mr. Omoto is the leader of the Votoms Research Committee.

Omoto: That’s right. I’ve been a fan of Votoms for a long time and wanted to build one someday. It is like a dream come true, also because of its size. Many ATs, especially the Scopedog, have been released in the past. Among them, Takara’s plamodel was very good, wasn’t it?

Mori: Yes, it was. It worked well.

Omoto: I’m sure everyone does this, but I was thinking to myself, “the Scopedog should be like this!” I think there’s something to say about that. I have my own image of the shape, and that makes it difficult. I was particular about the width and height of the torso, and also the height of the shoulders.

Mori: The shoulder armor has to float off the shoulders. It’s a bad idea to cover the shoulders. When viewed from the front, there should be three round peaks with the head at the top.

Omoto: Yes, yes. The top of the shoulder armor must be above the body. From Kunio Okawara’s design and from the TV screen, it is clear that if the shoulders are lowered, the silhouette of the Scopedog is off. I wanted to be careful not to make the waist too thin. Keep the waist thick and naturally, the volume of the thighs.

Mori: The thighs need to have a powerful thickness. (All nod)

Omoto: I also wanted to focus on the roundness of the head. I had an image, but I couldn’t come up with a specific structure. As I was building the mockup, I thought, “What the heck, I should do it this way.”

Everyone: That’s about right. (All laugh)

Omoto: Anyway, we all messed around with this mockup… (Laughs)

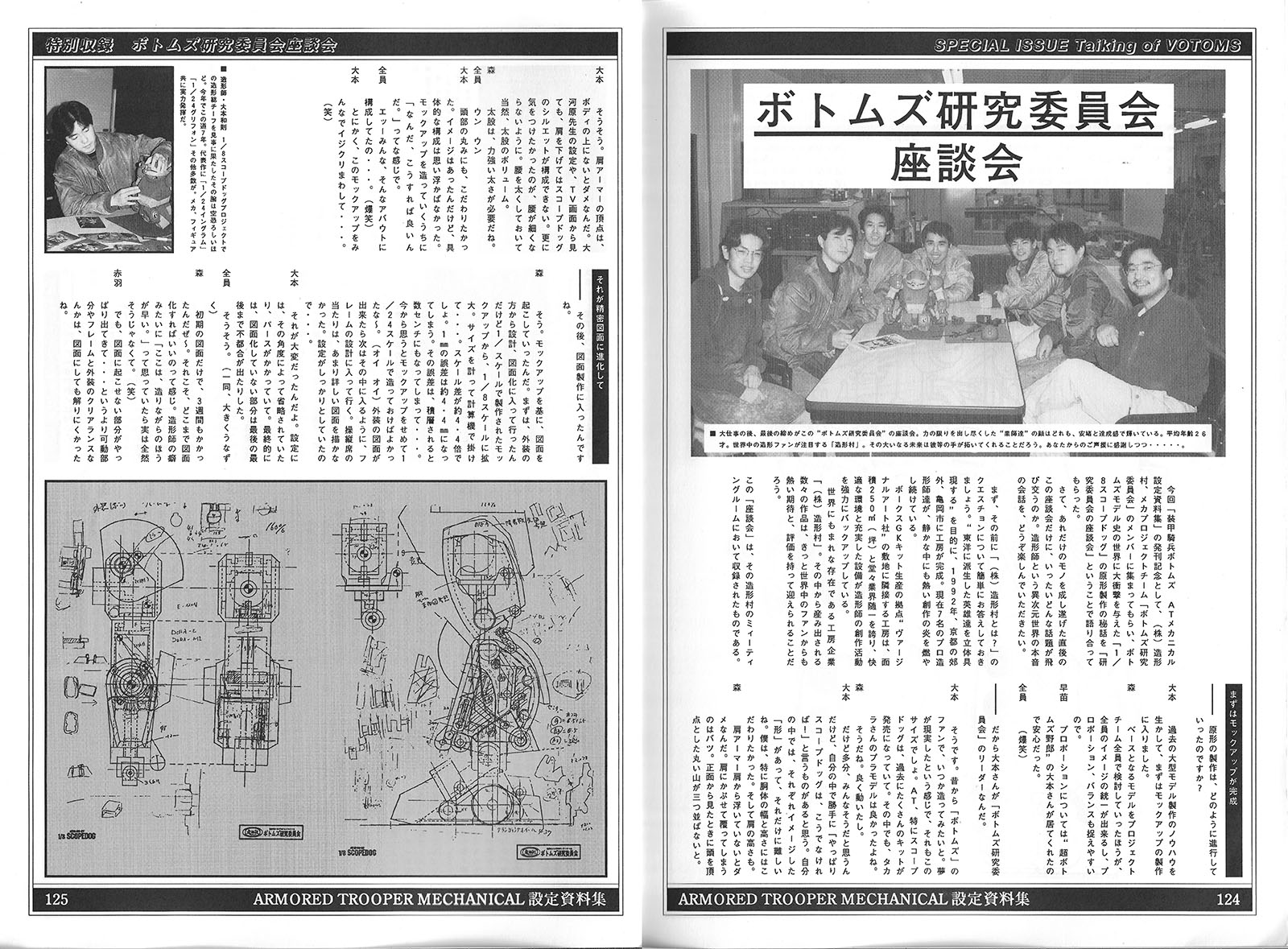

It evolved into precision drawings

Interviewer: After that, you started making drawings, didn’t you?

Mori: Yes, that’s right. I created the drawings based on the mockup. First, I started with the exterior design at the mockup scale and enlarged it to 1/8 scale. The size was measured and multiplied by a calculator. The scale difference is about 4.4 times [larger], so an error of 1mm became about 4.4mm. The errors added up to several centimeters when combined. Now that I think about it, we should have built the mockup at least in 1/24 scale.

Once the exterior drawings are done, the next step is to design the frame to fit inside it. I didn’t have to do a very detailed drawing for the area around the cockpit. The anime design was well defined.

Omoto: That was the hard part. Depending on the angle of the drawing, some details were omitted or perspective was applied. The parts that were not drawn were a problem to the very end.

(All nod broadly)

Mori: It took three weeks just for the initial drawings. It was like, “How much more do I need to draw?” The sculptor’s habit is to say, “It’s faster just to build it,” but that’s not actually the case at all. (Laughs)

Akabane: But there are still some things that can’t be done in a drawing. I mean, the moveable parts and the clearance between the frame and the exterior. It was hard to understand even if we drew it.

Omoto: When a moveable model of this size is made, there’s always a problem with the strength of the joints. We had to calculate that from the design stage. I was very surprised at the size of the model.

Mori: The strength of the urethane resin was calculated by quantifying how much weight it could bear and how strong it would be. It may have been overkill. But you’ll be relieved that we did this. Because of that, the number of parts increased.

Special polycap, exclusively developed

Interviewer: Is there something like a moveable system at this size?

Mori: It’s totally different from conventional moveable models. There were points such as “interlocking movement” and “because of the size, we need to take it this far.” That’s why we needed nuts and bolts. I went all over looking for the right size.

Omoto: We also developed a special polycap. It’s very good. Unlike previous polycaps, it’s strong and hard. The runner part is 3mm thick, so it can be used as well, just for garage kits.

Sanae: This polycap is really good. I wonder if we could sell it separately.

(Would you like to ask the planning department about it?)

Omoto: Because it’s a full moveable model, the first consideration was its proportions upon completion. And you can pose it. (It can also be fixed in place.) I think this kind of moveable model will be the standard from now on. It doesn’t look like it’s moving with polycaps, and it stands up properly.

(Everyone nods in agreement)

Mori: Because of this, nuts and bolts and exclusive polycaps were necessary and also needed to be strong.

The concept of interlocking includes proportion

Interviewer: The interlocking movement with the Muscle Cylinder (hereafter, MC) also had a big influence, didn’t it?

Omoto: It affects the range of motion rather than strength or proportion. The size and shape of the exterior cannot be changed. The frame also cannot be changed due to strength calculations. In such a situation, the limited range of the MC came into play.

Sanae: Still, you can enjoy a considerable range of movement.

Mori: The interlocking motion with MC was a mathematical matter in terms of drawing, and a problem of figures. Find the distance between two points by connecting three points and fixing one point. Basically, it’s a circular motion, but it’s like the relationship between bone and muscle.

The MC interlocking movement of the ankle deserves special attention. For the basic frame, we figured out the size necessary to support this weight and collected them so that they could move according to the movement of the MC. Rather than a model-like idea, I tried to reproduce it more like the real thing.

Omoto: That was quite a challenge, wasn’t it?

Mori: Actually, I was thinking about it all day long and thought, “This is it!” and then, five minutes later, I thought, “No good. It’s no good.” (Laughs)

Anyway, the ankle should be moveable in all directions. I had to calculate it so the stroke of the MC doesn’t protrude from the ankle. Furthermore, the MC and the exterior couldn’t interfere with each other. It was very hard work, because we had to be precise to the millimeter.

Akabane: The exterior, the frame, and the interlocking movement of the MCs. Furthermore, the issue of strength was the biggest point of this kit in any part.

(Everyone agrees)

Omoto: But I think it’s a bit much to have over 200 points just for the MC-related parts.

(Everyone laughs)

Sliding is added to the movement

Interviewer: By the way, the descent and landing [downform] mechanism of this model is very interesting.

Mori: This landing mechanism is a completely new concept that has never been seen before.

Omoto: That’s right. It’s a completely new system. From the beginning, this was the only system I could imagine. Rather than the hip joint sliding down, the waist slides upward. This is how the pose is achieved. I thought to myself, “Even if you stretch the arms straight down, they can never touch the ground.”

Mori: This part went easily. Precision, strength, clearance, and balance were determined. In particular, the issue of strength. We had to figure out how to make it strong, and in the end, we thought of the frame as the main part, and added reinforcement in the gaps.

Omoto: I’m a little worried about how much this new system will be accepted. But I have absolute confidence.

(All nod deeply)

The life of a weapon is simple and robust

Interviewer: Did you do location shooting before you started production?

Everyone: Yes, we did. (Laughs)

Mori: We went to a nearby construction site and took a lot of pictures of bulldozers, excavators, and trucks.

Omoto: I took the liberty of opening panels to look at engines without permission. (Laughs) Pretty tacky, huh? I felt like it was enough. The engine spaces of modern bikes and cars are beautifully designed.

Mori: Very simple molds, no details. Just a panel attached to the timing that stops at the hexagonal bolt. It’s like bending a steel plate.

Akabane: Come to think of it, the ceiling of the Zoukei-Mura office building was also a reference. (Laughs) The way the H-steel was connected, the welding afterwards, etc. It was quite a good reference.

Omoto: Anyway, it’s realistic. We embraced the know-how of construction machinery. It wouldn’t be suited to anything special.

Mori: The Scopedog isn’t a high-tech hunk or a fighter jet, but a jeep. So our watchword was…

Everyone: “Let’s go low-tech!” (Laughter)

Mori: I will not adopt a system that I’ve never seen before. The same is true for panel expressions. “Cords floating in the air like puffs, connecting armor to armor.” There is absolutely no such thing. They must be connected by hinges and bolts.

Omoto: It’s simple when you look at the driver’s seat of an excavator. There’s just a chair and a lever. Is there a thermometer for water temperature? I didn’t want the cockpit to look like a flower garden. It’s not like there are meters all lined up in a row.

Akabane: In the case of the AT, I guess the helmet goggle is a high tech chunk.

Mori: It’s a game machine. (Everyone laughs)

Interviewer: What parts do you want us to see?

Everyone: All of them. (Everyone laughs)

Akabane: I’d like you to see the arm punch mechanism, and the interlocking movement of the MCs in the arms. The magazine is also real.

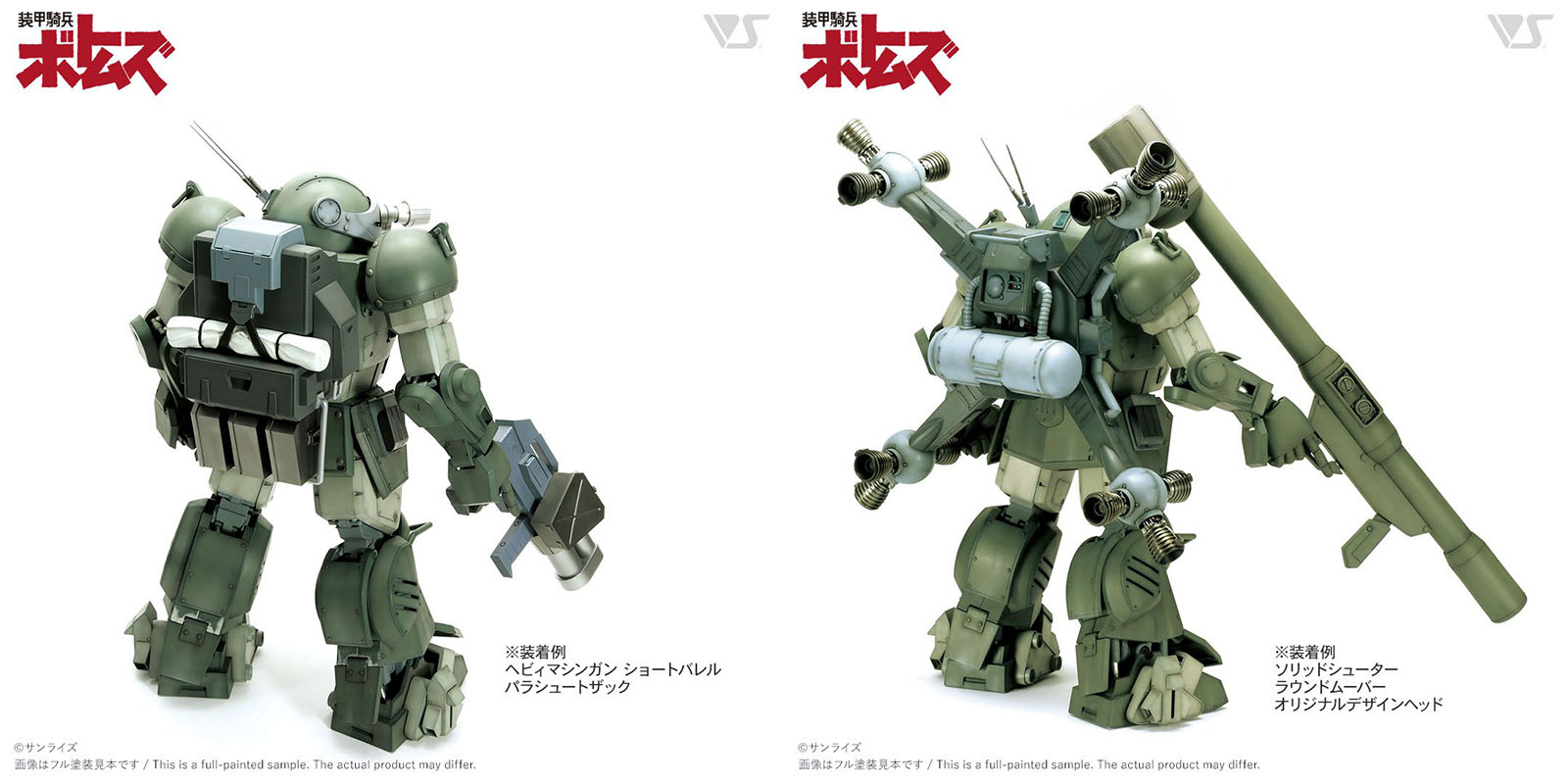

Sanae: The heavy machine gun is also well done to reduce the weight. There is a meaning in the division of these parts. It’s something to look forward to in the future.

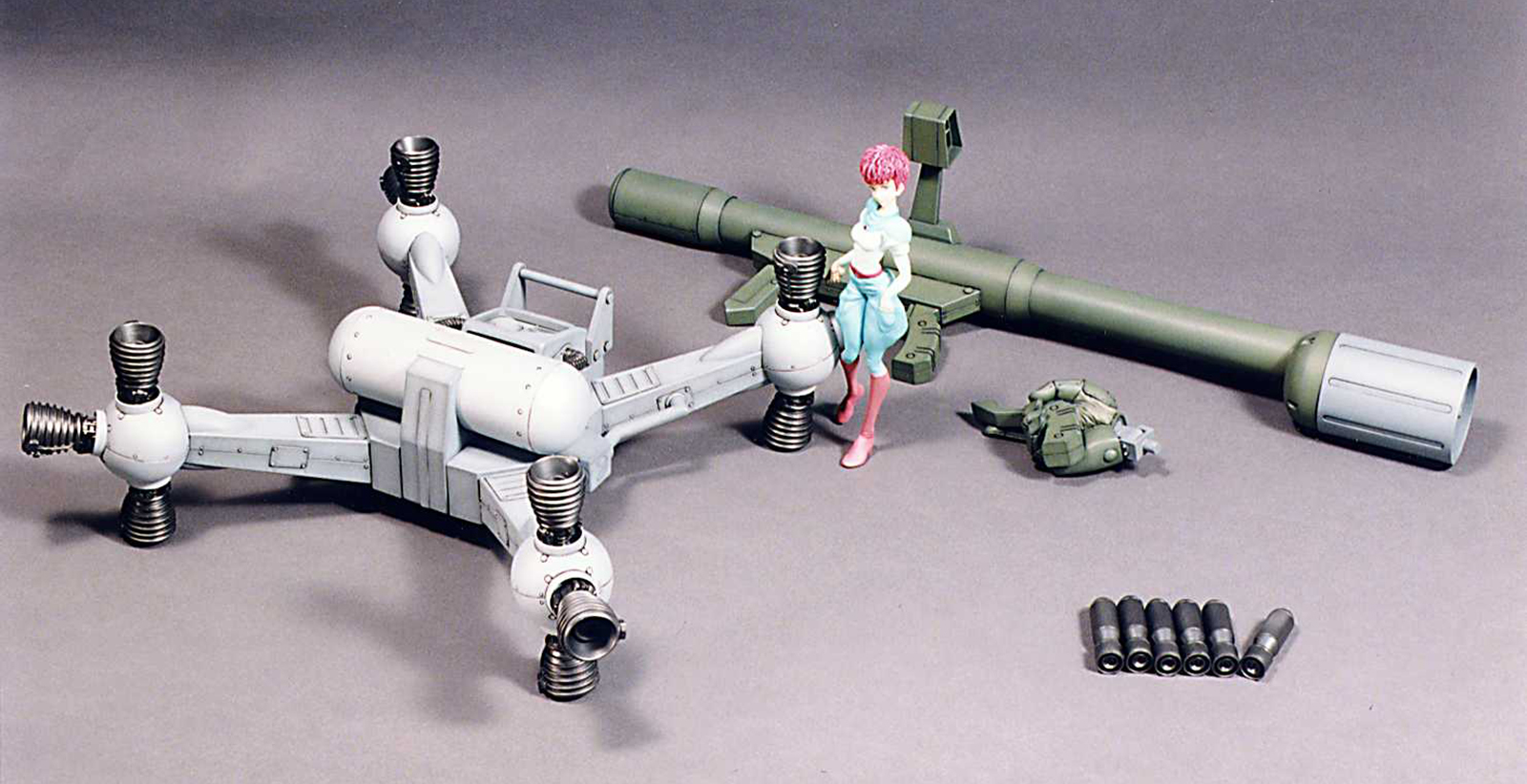

Enou: I want you to enjoy Chirico [the figurine] as well. (Laughs)

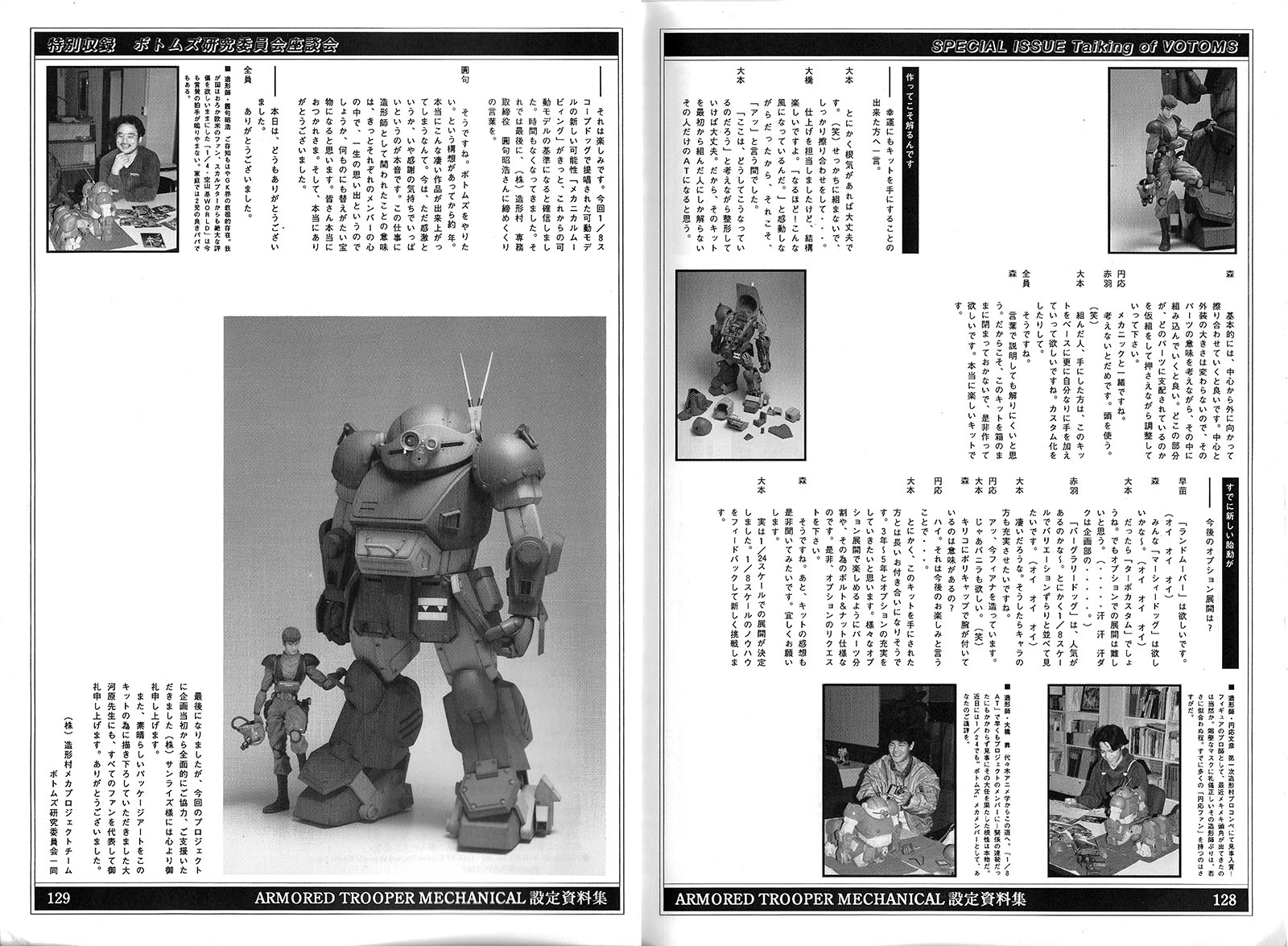

Mori: Anyway, each part has its own meaning. Parts are divided into details required for 1/8 scale, and we don’t over-express anything. I didn’t want to simply increase the number of parts or moveable parts that weren’t suitable to the scale. Only necessary elements are reproduced.

Omoto: It may seem like fun to create a single work of art with several people, but it’s quite a task. It’s pretty hard. It’s very difficult to leverage the techniques of all the project team members and to pace it properly. Too early is no good and too late is even worse. (Laughs) There are many things that need to be done. Also, each sculptor has their own habits.

Mori: Not so much habits as strengths and weaknesses.

Omoto: If you’re good at precision, you can be in charge of that area, and if you’re good at balance, you can take that. Each person’s area of expertise is fully utilized and assembled into a single body of work. We had meetings over and over again. (All agree)

Mori: In the prototype stage, the support of Virginal Art was very helpful. When we duplicate with silicon gum, there are inevitably some discrepancies. So this time, I asked them to use a special silicon.

Sanae: You don’t usually notice shrinkage in a single part, but if it overlaps with layers, the shrinkage could be a millimeter or more. We had a lot of meetings.

Omoto: Naturally, the parts are designed with molding of the product in mind, so the accuracy of the kit will be correct.

You have to build it to understand it

Interviewer: What would you like to say to those who are lucky enough to obtain the kit?

Omoto: If you’re patient, you’ll be fine. (Laughs) Don’t be in a hurry, just fit it together well.

Ohashi: I was in charge of the finishing touches, and it was a lot of fun. “I see! That’s how it is!” I was so impressed, I was just saying, “oooh!”

Omoto: It’s okay if you think, “Why is it like this?” while you build it. I think it will become a unique AT that can only be understood by someone who builds it from the ground up.

Mori: Basically, it’s good to fit it together from the center toward the outside. The size of the center and the exterior will not change, so it’s good to think about the meaning of the parts while you incorporate them into that. Make temporary assemblies and adjust them while holding down the dominant parts.

Enou: Just like a mechanic.

Akabane: You have to think. Use your head. (Laughs)

Omoto: I hope those who obtain and assemble this kit will further modify it in their own way, and customize it.

(Everyone agrees)

Mori: I think it’s difficult to explain in words. That’s why I’d like you to build this kit instead of keeping it in a box. It’s a really fun kit.

A new movement is already underway

Interviewer: What do you have in mind for the future development of options?

Sanae: I want to do a Round Mover.

Mori: I think everyone wants a Marshy Dog.

Omoto: Then it would be a Turbo Custom. But I think it would be difficult to develop it as an option.

(The planning department breaks a sweat…)

Akabane: I wonder if the Burglary Dog is popular. Anyway, I’d like to see a lot of variations side by side at 1/8 scale.

Omoto: It would be great. Then I’d like to have a full lineup of characters too.

Enou: Yes, I’m working on Fyana now.

Omoto: Then I want Vanilla too. (Laughs)

Mori: Would it make sense for Chirico to have polycap arms?

Enou: Yes, that’s something to look forward to in the future….

Omoto: Anyway, I think we’ll have a long relationship with people who get this kit. We’d like to enhance the options for the next 3 to 5 years. Please send us your requests for options.

Mori: Yes, and I’d love to hear your impressions of the kit. Thank you in advance.

Omoto: Actually, we have decided to develop in 1/24 scale. We’ll try new challenges based on our know-how at 1/8 scale.

Interviewer: I’m looking forward to that. I am convinced that the “mechanical moving” possibilities proposed in the 1/8 Scopedog will be the standard for the future of mobility models. Time is running out. Now I’d like to ask Akihiro Enku, Senior Managing Director of Zoukei-Mura, Inc. for closing remarks.

Enku: It’s been about a year since I had the idea to do Votoms. I can’t believe that such an amazing work of art has really been completed. Right now, I’m just thrilled, or rather, I’m filled with gratitude. I’m sure that in each member’s heart, the meaning of being involved in a work like this will become a lifetime memory for a sculptor, a treasure that cannot be replaced by anything else. Thank you all for your hard work.

Interviewer: Thank you very much for your time today.

Last but not least, we would like to express our sincere gratitude to Sunrise Inc. for their full cooperation and support from the beginning of this project. We would also like to thank Mr. Kunio Okawara for drawing the wonderful package art for this kit. We express our gratitude on behalf of all fans.

– Zoukei-Mura mecha project team/Votoms Research Committee

Video Presentations

Featuring Series Creator Ryosuke Takahashi, Character Designer Norio Shioyama,

and Mecha Designer Kunio Okawara. Held to commemorate the 1/8 Scopedog rollout.

The continuing pursuit

Volks and Votoms have been interlinked since the 1/8 Scopedog first appeared in 1995. The company launched a series of 1/24 garage kits around the same time that have been periodically reissued since then. Meanwhile, others have followed their lead, digging deep into the interior mechanisms of this intriguing machine.

A.T. Votoms • A.T. Complete Report

装甲騎兵ボトムズ AT完全報告書

With the arrival of the Pailsen Files OVA series came the “Scopedog 21C” (for 21st Century), refined for CG animation and new products. This book (a spinoff of Great Mechanics magazine), examined the entire refining process, which covered every part from head to toe. There’s also another extensive A.T. catalog and a general anime/game overview.

Color and B&W, 148 pages

Futabasha, June 2007

Scopedog 21C Master Book

装甲騎兵ボトムズ スコープドッグ21C マスターブック

A super-deluxe examination of the design work that went into the refined Scopedog 21C, along with a photo-feature of a custom-built model and a high-quality collection of A.T. designs from anime and games.

Color and B&W, 128 pages

SB Creative, Oct 2009